Description

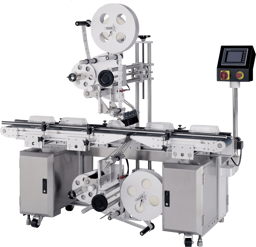

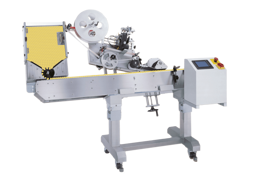

LAB8221 Top and Bottom Labeler for Flat Surfaces:

Innovative Solution for Various Industries

The LAB8221 Top and Bottom Labeler impresses with its robust construction and is specifically designed

for industries such as food, cosmetics and logistics. With the capability for top and bottom labeling,

it offers a flexible solution for accurately labeling flat products and packages of various sizes.

User-friendly control system for optimized workflow:

With its intuitive control system, the LAB8221 facilitates easy operation, even for inexperienced staff.

The logical user interface optimizes workflow and promotes efficient collaboration. The customization

of the control system contributes to making the labeling process effortless.

Cost-effective and powerful:

As the most economical and efficient investment in its class, the LAb8221 allows processing a wide range

of label sized through simple adjustments. It's high-speed performance and stability surpass comparable

machines, maximizing productivity while ensuring cost efficiency.

Innovative design for optimal labeling results:

The unique dual-head design of the LAB8221 simplifies top and bottom labeling in a single pass,

saving time and boosting efficiency. The durable construction of 304 stainless steel and anodized aluminum

complies with Good Manufacturing Practices (GMP) standards, making the LAB8221 a reliable

choice for long-term use, even in demanding environments.

With the LAB8221 Top and Bottom Labeler, businesses make an innovative choice that combines efficiency,

user-friendliness and durability. Enhance your labeling process with this top-notch solution and secure lasting success!

Highlights of the LAB8221:

- The LAB8221 utilizes S304 stainless steel as its main component, ensuring easy maintenance and a long machine lifespan.

- The precision inverter speed control is stable and durable, with a minimal inaccuracy of +-0.5% at various speeds.

- The dual conveyor design is suitable for high-speed labeling.

- The connection plate between the footrest and conveyor is made of high-quality, unpainted aluminum alloy,

while the double foot stands provide maximum stability in a compact design.

Technical Specifications

| Model | ADR LAB8221 |

| Maximum label height | 150mm |

| Maximum label length | 300mm |

| Spool Diameter | 76mm |

| Dispensing Speed | 40m/min max. |

| Conveyor Speed | 40m/min max. |

| Conveyor Width | 160mm |

| Applicator Height | 150mm/200mm |

| Dimension (mm) | 1620 (L) x 900 (W) x 1500 (H) |

| Power Consumption | 220/110 Vac 50/60Hz 1 phase |

| Supply Voltage | 825VA |

| Net. weight | Ca. 120 kg |

| Certifications | FCC, CE, RoHS |

Would you like more information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet