Description

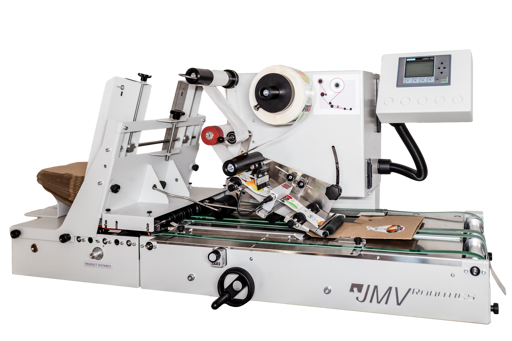

LAB8020 - Tabletop Labeling Machine for Efficient and Flexible Labeling

Explore the versatile world of labeling with ADR AG's LAB8020 – your solution for efficient and mobile labeling

in small production runs. This top-labeling machine achieves impressive production speeds of up to 60 containers per minute,

catering to your demands. Ideal for industries such as food, pharmaceuticals, cosmetics, and logistics, the LAB8020 offers

a flexible solution for precise product labeling.

Whether in production, retail, or logistics, the LAB8020 adapts to your specific requirements, ensuring reliable labeling

for various applications.

Portable Design for Optimal Adaptability:

The innovative design of the LAB8020 allows effortless movement and setup wherever needed – on a table, workbench,

or in line for automatic applications. This lightweight and portable machine provide flexibility beyond what heavier models can offer.

User-Friendly Excellence: Quick Setup and Easy Operation:

Equipped with integrated operating instructions, a straightforward troubleshooting guide on the interface, and handwheels

for uncomplicated adjustments, the LAB8020 is quickly operational. Benefit from user-friendly operation, facilitating smooth

transitions between different labeling requirements.

Robust and Maintenance-Friendly: Durable Performance to GMP Standards:

Compliant with strict Good Manufacturing Practices (GMP) standards, the LAB8020 is constructed from high-quality 304 stainless steel

and anodized aluminum. Its robust design not only allows for swift issue resolution but also shields the machine from the challenges

of demanding environments. Rely on the durability and easy maintenance of the LAB8020 for a dependable labeling solution.

Optimize your production processes with the LAB8020 – your mobile and efficient tabletop labeling machine for sophisticated applications.

Key Features of the LAB8020:

- Precisely track labeling progress during production runs.

- All components synchronize for seamless production.

- Stored settings and information remain intact even after extended inactivity.

- Integrated feature ensures smooth synchronization of labeler and hot foil printer, ensuring precise code placement.

- Modular design concepts simplify maintenance, while flexible adjustments allow rapid adaptation to production schedule changes.

- High-quality stainless steel and anodized, hardened aluminum alloys ensure the machine's longevity and stability.

The LAB8020 can be operated entirely manually:

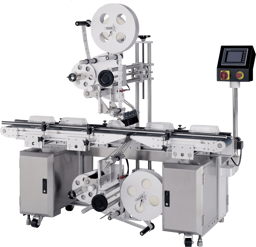

Or optionally equipped with an input feeder (unit for product feeding):

Technical Specifications

| Model | ADR LAB8020 |

| Max. label height | 120mm |

| Max. label length | 300mm |

| Operation | Standalone with internal controller |

| Conveyor width / Max product width | 160mm |

| Max. product height | 120mm |

| Dispensing speed | 16m/min max. - Approximately 60 containers per minute (depending on container sizes) |

| Spool diameter | 76mm |

| Power supply | 220/110 Vac 50/60Hz single phase |

| Option 1 | Input-Feeder |

| Option 2 | Hotfoil printer for EXP, LOT numbers, letters 2mm, 2,5mm, 3mm text height available |

| Option 3 | Longer conveyor |

| System dimensions (mm) | 1100mm (length) x 550mm (Width) x 820mm (Height) |

| Certifications | FCC, CE, RoHS |

Would you like more information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet