Description

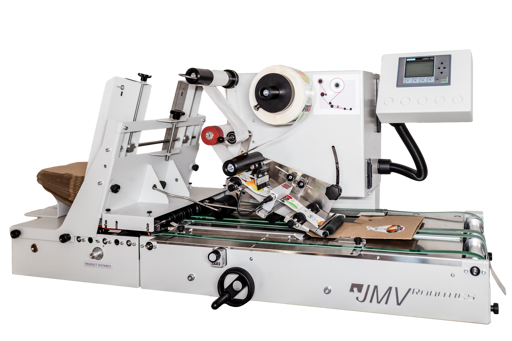

The ROTOPRESS was designed to facilitate different manual paper or cartongluing and pressing jobs. In use it will replace the often mandatory production steps of separate down weighting, pressing and pushing. Integrating gluing and pressing in one system and one work pass will significantly enhance the productivity. The ROTOPRESS is especially suitable for all cartonmaterials which suffer from high restoring forces after gluing and therefore require high pressure.

Two massive double pinch rollers, operating simultaneously with variable pressure, generate durable adhesive bonding. The flow pass speed can be controlled. A movable material side stopper guarantees consistent product infeed and destacking. The outfeed stacker is adjustable in height and width and can be tailored to accommodate different products and changing production volumes. The control panel features a main power switch, a run direction switch, a startbutton and a speed controller.

A standard safety feature is the “emergency off” bar, conveniently located in the main operation area of the machine. The ROTOPRESS is equipped with ROPI’s well known HandGluingSystem. The ballpoint principle of the pencil allows to generate consistent clean glue dots or lines. By use of custom templates even complicated, reproducible glue lines can be generated. Besides the standard nozzle with a diameter of 4 mm also removable nozzles with 3 mm (for fine paperproducts) and 6 mm diameter (for heavy paperboards) are available. This allows accurate gluing in userdefined linestrength. The handgluingsystem works with all commercially available cold glues, featuring a viscosity of up to 2.000 mPa.

PowerSpecifications:

220 VAC, 50/60 Hz, 250 Watt

Reviews

Be the first to review this item

There are no reviews yet