Description

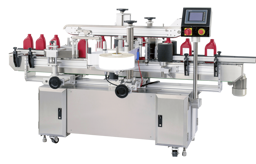

LAB8622 Front and Back Labeler for Various Product Shapes

The LAB8622 sets new standards for advanced labeling capabilities and manufacturing efficiency.

With its innovative labeling system, it not only allows for effortless handling but also delivers

impressive precision and speed in labeling both the front and back of products. This unique combination

of cutting-edge technology and cost-effective labeling processes makes the LAB8622 the essential solution

for enhanced production performance and competitiveness in your industry-regardless of the sector.

Flexible Mobility and Integration:

The LAB8622 offers outstanding labeling performance and flexible mobility, whether used

as a standalone unit or seamlessly integrated into your production line. Tool-free adjustments for

guide rail, side pressure guidance and applicator enable effortless adaptation to various product shapes.

This versatility ensures optimal machine arrangements and maximum efficiency in different production environments.

Versatile Design for Customized Requirements:

The design of the LAB8622 goes beyond the conventional by providing a two-sided application

design for labeling the front and back. This flexibility extends further with options for single-sided

application and an available wrap-around station. The LAB8622 is thus a versatile solution that

effortlessly and precisely meets various production requirements, maximizing the efficiency and flexibility

of your processes.

User-Friendly Durability:

The LAB8622 impresses not only with its innovative efficiency but also with its user-friendliness.

Integrated operating and troubleshooting instructions make handling easy. Thanks to handwheels,

quick setup and effortless switching become a breeze. Consistent adherence to Good Manufacturing Practices (GMP)

standards, combined with high-quality materials such as 304 stainless steel and anodized aluminum, ensures durability

and makes the LAB8622 the optimal labeling solution.

Highlights of the LAB8622

- Track production progress precisely with the label counting function.

- Side Pressure Device: The product alignment system in the feed maintains a consistent product

position and separates the bottles at an equal distance. - Top Pressure Device: Simultaneously applies pressure from above to support the products and

ensure stable bottle movement. - Save up to thirty settings for future use, saving valuable time on data re-entry..

- Modular design concepts simplify maintenance, while flexible adjustments allow rapid

adaptation to production plan changes. - The use of high.quality stainless steel and anodized, hardened aluminum alloys ensures

the longevity and stability of the machine.

Technical Specifications

| Model | ADR LAB8622 |

| Label Size | H:150mm x L:300mm Max. |

| Maximum Label Roll Size | 300mm |

| Label Roll Core | 76mm |

| Conveyor Width | 100 mm |

| Dispensing Speed | 30m/min max. |

| Conveyor Speed | 5~30 m/min. |

| Applicator Height | 150mm |

| Dimension (mm) | 2404mm (L) x 1547mm (W) x 1354mm (H) |

| Supply Voltage | 220/110 Vac 50/60Hz 1Phase |

| Power Consumption | 900 VA |

| Net Weight | Ca. 240 kg |

| Certification | FCC, CE, RoHS |

Would you like more information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet