Description

Innovative Labeling Solution: LAB8521 for uniquely shaped products!

LAB8521 is the smart choice for labeling unusually shaped products that cannot stand securely on their own.

Designed to apply a complete or partial label horizontally on bulky round containers, this machine stands out

for its exceptional dispensing speed, flexibility, and reliability.

Unique design for horizontal labeling: Precise and efficient!

ADR AG has specifically developed the LAB8521 model for horizontally labeling slender, non-freestanding cylindrical

containers such as pens, test tubes, syringes, and lipsticks. The unique horizontal labeling structure ensures fast, stable,

and precise labeling, eliminating distortions and ensuring excellent labeling efficiency. The machine's inclined roller conveyor

secures the product laterally, allowing precise labeling during passage through the label head.

User-friendly and adaptable: LAB8521 makes it possible!

LAB8521 has few moving parts, and adjustments are easily made. Switching between different containers is simple by exchanging

the container. The unique Auto-Feeder design and the inclined conveyor belt made of specially engineered plastic rollers minimize

the risk of damage to sensitive containers. The machine is designed for containers with a diameter of 10-25 mm and can be optionally

equipped with a printer.

Built to last: LAB8521 prioritizes longevity!

Strictly adhering to Good Manufacturing Practices (GMP) standards, LAB8521 is made of 304 stainless steel and anodized aluminum,

carefully treated to protect against harsh environments. This durability makes it a solid choice for the longevity of labeling machines.

Choose LAB8521 for a reliable and durable labeling solution!

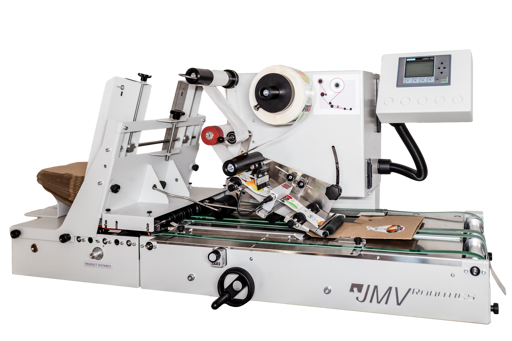

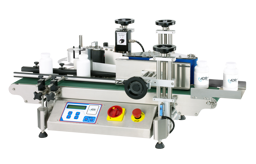

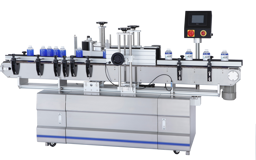

Get a first impression of LAB8521:

Technical Specifications

| Model | ADR LAB8521 |

| Max. label height | 150mm |

| Max. label length | 75mm |

| Maximum Bottle Diameter | 10-24 mm diameter. |

| Operation | Standalone with internal controller |

| Conveyor width / Max product width | 100 mm |

| Applicator Height | 150 mm |

| Dispensing Speed | 40m/min max. |

| Spool Diameter | 76 mm |

| Power Consumption | 840 VA |

| Supply Voltage | 220/110 Vac 50/60Hz single phase |

| Dimension (mm) | 2000mm (L) x 1100mm (W) x 1550mm (H) |

| Net Weight | 175 kg |

| Certifications | FCC, CE, RoHS |

Would you like more Information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet