Description

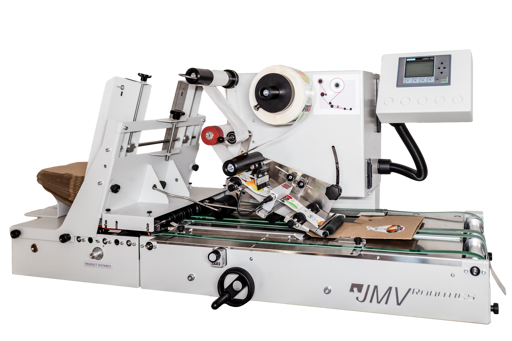

Efficient labeling with the LAB8515:

Vertical Wrap-Around Automatic Labeling Machine

EDiscover the innovation of the LAB8515 - a state-of-the-art vertical wrap around automatic labeling machine

with a robust and customizable design. The LAB8515 impresses with remarkable versatility, finding

applications in various industries, from food and beverages to pharmaceuticals and packaging.

Intelligent control system for simplicity and efficiency

Equipped with an intelligent control system, the LAB8515 ensures not only smooth operation

but also facilitates the integration of new personnel into production. The logical structure of

the control system optimizes workflow for more efficient production.

Flexibility and reliability for long-term production

The LAB8515 exceeds expectations by not only offering a variety of additional functions but

also expanding existing functions for future production requirements. Possible expansions

include dispensing and collecting plates as well as a Hot-Foil Printer.

Durability meets user-friendly operation

a robust construction that withstands the demands of challenging environments.

In strict accordance with Good Manufacturing Practices (GMP) standards, the machine is not only

reliable but also easy to maintain. User-friendly features enable quick machine adjustments and conversions.

Choose the LAB8515 and experience a powerful labeling solution that combines the highest quality,

adaptability and reliability. Optimize your production processes and invest in a machine that not only

meets current requirements but is also prepared for future challanges.

Highlights of the LAB8515

- 30 Cross-Memory Modules: Optimize labeling settings for increased productivity and quick

integration of new personnel. - Label Delay Function: Precise adjustments with automatic calculation of dispensing speed and position.

- Preset Function: Effortlessly track the number of labeled labels and automate the stop after

a predefined product quantity with the convenient batch function. - Integrated Troubleshooting: The built-in troubleshooting assists in finding quick solutions

and maintaining the production line. - The machine is testes according to European CE and UL standards.

| Model | ADR LAB8515 |

| Max. label height | 170mm |

| Max. label length | 300mm |

| Maximum Bottle Diameter | 180 mm |

| Operation | Standalone |

| Conveyor Width | 160 mm |

| Dispensing Speed | 40m/min max. |

| Conveyor Speed | 5~23 m/min. |

| Applicator Height | 170mm |

| Dimension (mm) | 2450mm (L) x 1320mm (W) x 1350mm (H) |

| Supply Voltage | 220/110 Vac 50/60Hz 1 phase |

| Power Consumption | 660 VA |

| Net Weight | 200 kg |

| Certification | FCC, CE, RoHS |

Would you like more information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet