Description

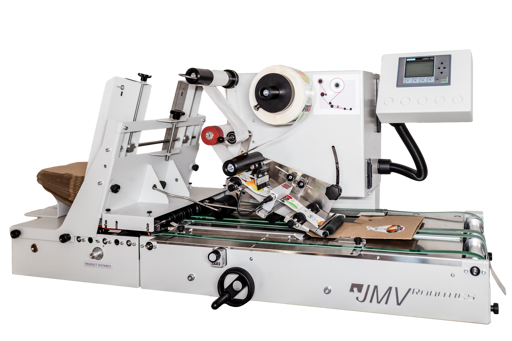

LAB8252 - Corner Wrap Labeler for Carton Boxes

Discover the LAB8252 by ADR AG, specifically designed for the efficient application of tamper-evident labels,

serving to detect tampering or unauthorized openings of products or packaging.

The LAb8252 is the perfect device for industries such s pharmacy, food, consumer goods and cosmetics.

Highest Performance with LAB8252:

The LAB8252 impresses with exceptional speed and precision. It's dual labeling head allows

simultaneous application of labels on the edges of cardboard in an L-shape. The thoughtful design enables

efficient adjustment of the applicator position without the need for complicated part changes.

Easy handling and robust construction according to GMP standards make it the ideal choice for continuous operation in you business

Versatile Applications with LAB8252:

The LAB8252 is an outstanding example of high-quality, versatile labeling machines. With continous, high-speed labeling

and individual adjustments via the touchscreen, this model offers a built-in guiding mode and error troubleshooting functions.

This allows both trained and new personnel to efficiently operate the machine and meet production requirements.

Efficiency Enhancement through innovative Technology:

Experience the performance of LAB8252 and optimize your operations. Order now and increase the efficiency

of your product labeling with state-of-the-art technology for reliable and user-friendly labeling solutions.

Highlights of LAB8252

- Precisely track production progress with the label counting function.

- LAB8252 features a durable PLC control system that preserves standard values and memory

even after extended idle times. - Save up to 30 settings for future use, saving valuable time on data entry.

- Modular design concepts simplify maintenance, while flexible adjustments enable quick changes

in production planning. - The use of high-quality stainless steel and anodized, hardened aluminum alloys ensures durability

and stability of the machine.

| Model | ADR LAB8252 |

| Max. label height | 80mm |

| Max. label length | 300mm |

| Maximum product size | 375mm x 152mm |

| Conveyor width / Max product width | 165-228mm (weitere Breiten erhältlich) |

| Conveyor belt speed | 40m/min max. |

| Dispensing speed | 40m/min max. |

| Spool diameter | 76mm |

| Power supply | 220/110 Vac 50/60Hz 1 phase |

| Power consumption | 820VA |

| Dimensions (mm) | 1700mm (L) x 950mm (W) x 1500mm (H) |

| Net weight | Ca. 120 kg |

| Certifications | FCC, CE, RoHS |

Would you like more information?

Click here to download the datasheet.

Reviews

Be the first to review this item

There are no reviews yet