Beschreibung

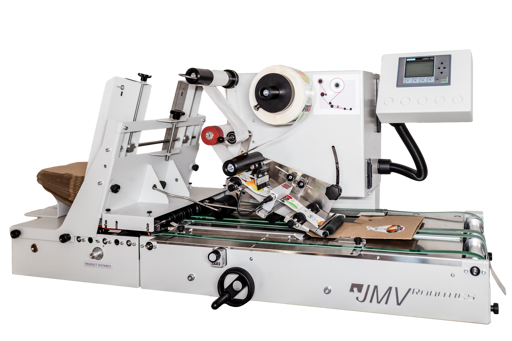

LAB8501 Etikettierlösung: Effiziente und Flexible Produktkennzeichnung

Anpassungsfähiges Design für optimale Flexibilität:

Entdecken Sie mit dem LAB8501 eine Etikettierlösung, die sich durch ein anpassungsfähiges, modulares Design auszeichnet

und mühelos auf spezifische Anforderungen modifizieren lässt. Diese innovative Lösung bietet vielseitige Einsatzmöglichkeiten

für Behälter jeder Form, sei es in der Lebensmittel- und Getränkeindustrie, pharmazeutischen Produktion, Kosmetik-

und Pflegeproduktherstellung oder anderen Industriezweigen.

Integrierte Produktionsmöglichkeiten für höchste Effizienz:

Das LAB8501 ermöglicht sowohl eigenständige Anwendung als auch nahtlose Integration in Produktionslinien mit verschiedenen Maschinen.

Durch zusätzliche Funktionen wie Drucker und Drehtische wird die Funktionalität maximiert, um den Anforderungen

verschiedener Produktionsprozesse gerecht zu werden.

Flexibilität dank innovativer Technologie:

Das personalisierte Technologie-Steuerungssystem, verstellbare Handräder und benutzerfreundliche Zubehörteile gewährleisten

nicht nur Stabilität, sondern auch eine mühelose Anpassung an spezifische Anforderungen in unterschiedlichsten Branchen.

Präzise Kennzeichnung für vielfältige Behälterformen:

Der Rundum-Etikettierer des LAB8501 eignet sich hervorragend für alle Arten von runden Glas- und Kunststoffbehältern,

die eigenständig aufrecht stehen können. Diese spezielle Lösung wurde entwickelt, um präzise Etikettierung zu ermöglichen

und ist somit die ideale Lösung für individuelle Kennzeichnungsanforderungen.

Investieren Sie in das LAb8501, um Ihre Produktkennzeichnung zu optimieren und von einer erstklassigen, flexiblen Etikettierlösung

zu profitieren. Erfahren Sie mehr über diese innovative Etikettiermaschine und deren vielfältige Einsatzmöglichkeiten in Ihrer Branche.

Machen Sie sich einen ersten Eindruck von der Maschine:

Dieses Video zeigt die LAB8501 Etikettiermaschine mit einem 3-Punkt-System.

Dank des 3-Punkt-Systems sind genaueste Ergebnisse auch mit Etiketten, die länger als 300mm sind möglich.

Vorder- und Rückseitenetikettierung

Auch die Anforderung an eine Vorder- und Rückseitenetikettierung sind mit dem 3-Punkt-System

der LAB8501 mit zufriedenstellenden Ergebnissen zu erfüllen.

Dieses

Video zeigt die Etikettiermaschine LAB8501 mit dem 3-Punkt-System für

Vorder- und Rückseitenetikettierung in einem Arbeitsgang.

Option um die Erweiterung eines Thermodruckers

Auch bietet die LAB85001 die Möglichkeit einen Thermodrucker zu integrieren. Hierbei werden Geräte der Marke TSC verwendet.

Der Etikettierautomat kann mit dem gesamten TSC-Sortiment an industriellen Thermodruckern geliefert werden.

Sie haben die Auswahl zwischen der PEX1100-Serie

(TSC PEX1120, PEX1130, PEX1160) und der PEX1200-Serie ( TSC PEX1220, PEX1230, PEX1260).

Technische Daten

| Model | ADR LAB8501 |

| Max. Etikettenhöhe | 150mm |

| Max. Etikettenlänge | 300mm |

| Max. Produktdurchmesser | 100mm |

| Betrieb | Standalone |

| Breite des Förderbandes/ Maximale Produktbreite | 100mm |

| Etikettenkopfhöhe | 150 mm (200mm optional) |

| Ausgabegeschwindigkeit | 40m/min max. |

| Förderbandgeschwindigkeit | 5~23 m/min. |

| Spulendurchmesser | 76mm |

| Stromversorgung | 220/110 Vac 50/60Hz Einphasig |

| Stromverbrauch | 760 VA |

| Maschinenmaße | 2004mm (L) x 1054mm (W) x 1043mm (H) |

| Nettogewicht | ca. 150kg |

| Zertifizierung | FCC, CE, RoHS |

Sie möchten weitere Informationen?

Klicken Sie hier um das Datenblatt zu downloaden.

Sie suchen nach anderen Funktionen, die Sie für Ihre Projekte benötigen?

Wir produzieren Etikettiermaschinen für die verschiedensten Anforderungen.

Kontaktieren Sie uns und gemeinsam werden wir eine Lösung finden.

Bewertungen

Geben Sie die erste Bewertung ab

Es liegen keine Bewertungen vor